Designmaster from Groupdiy sent me an interesting PM regarding my Power Distribution plans.

"How do you want to make the 5V for the ADC. For example the PCM4202 needs 65mA for the 5V analog voltage. You have 18V going to the board.

This will result in over 0.8W of dissipation loss and will generate heat which is not the best for thermal noise performance. I would recommend an additional supply rail with lets say more than 5V for the ADC or DAC may be 7V than you have the option to use a 5V voltage regulator on the board and than you will get a nice and low-noise supply.

How about 48V for phantom powering if you plan to go for a MIC Input board with integrated ADC? "

That made me think a little further. My initial plan was to only have a single "Hard Drive" type power connector. However, I soon needed more connectors (5.. not 4... )

So, a little more thought, means that I could have a 4 way digital connector and a separate analog connector. It would also means that my supply boards can be completely separate on the board.

Nice :)

Tuesday, November 21, 2006

Tuesday, November 14, 2006

Getting back to basics

I've been so distracted by new projects recently, that I forget why I did all this:

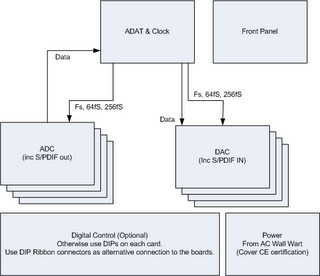

I wanted an AD-DA with ADAT connectivity. Simple. Easy.

A recent post on Groupdiy by Svart reminded me of this. I've spent so much time trying to get the interconnect sorted, that I lost sight of what I wanted.

So -- with the interconnect almost sorted - it'll soon be time to get back to what I really wanted to do :)

3 actions:

1 - complete standardised interfconnect

2 - Get PCM4204 and PCM4104 EVM's and ADAT Cards made - test.

3 - If successful, optimise EVM's for easy DIY production. :)

I wanted an AD-DA with ADAT connectivity. Simple. Easy.

A recent post on Groupdiy by Svart reminded me of this. I've spent so much time trying to get the interconnect sorted, that I lost sight of what I wanted.

So -- with the interconnect almost sorted - it'll soon be time to get back to what I really wanted to do :)

3 actions:

1 - complete standardised interfconnect

2 - Get PCM4204 and PCM4104 EVM's and ADAT Cards made - test.

3 - If successful, optimise EVM's for easy DIY production. :)

Tuesday, October 24, 2006

Motherboard connectors (attempt 1)

To make the system work with ribbon connectors etc, here's a suggested pin requirement. Please comment...

it makes 19x2 in total... 19x 0.1" = 1.9" long, 0.2" wide connector.

POWER

+18VDC - Analog

AGND

-18VDC - Analog

AGND -

Analog12VDC - Digital Supply

DGND

Requirement: 3x2 0.1" connector

Clocks

FS - Typically 44.1kHz

DGND

256fS - 256xSampling Frequency

DGND

512fS - 512xSampling Frequency

DGND

Requirement: 3x2 0.1" Connector

Control

SPI - CS (SPI Chip Select)

DGND

SPI - SCLK (SPI Serial Clock)

DGND

SPI - DIN (SPI Data In)

SPI - DOUT (SPI Data Out)

SCK - I2C (I2C Clock)

DGND

SDA - I2C (I2C Data)

DGND

Requirement: 5x2 0.1" Connector

Audio (Left Justified)

LRCK (Typically the word clock brought in from the clock source)

DGND

BCK (128fS or 256fs)

DGND

Data (Left Justified Data)

DGND

AES+ (S/PDIF or AES Data)

DGND

AES- (S/DPIF or AES Data)

DGND

EXTRA1

DGND

EXTRA2

DGND

EXTRA3

DGND

Requirement: 8x2 0.1" Connector

it makes 19x2 in total... 19x 0.1" = 1.9" long, 0.2" wide connector.

POWER

+18VDC - Analog

AGND

-18VDC - Analog

AGND -

Analog12VDC - Digital Supply

DGND

Requirement: 3x2 0.1" connector

Clocks

FS - Typically 44.1kHz

DGND

256fS - 256xSampling Frequency

DGND

512fS - 512xSampling Frequency

DGND

Requirement: 3x2 0.1" Connector

Control

SPI - CS (SPI Chip Select)

DGND

SPI - SCLK (SPI Serial Clock)

DGND

SPI - DIN (SPI Data In)

SPI - DOUT (SPI Data Out)

SCK - I2C (I2C Clock)

DGND

SDA - I2C (I2C Data)

DGND

Requirement: 5x2 0.1" Connector

Audio (Left Justified)

LRCK (Typically the word clock brought in from the clock source)

DGND

BCK (128fS or 256fs)

DGND

Data (Left Justified Data)

DGND

AES+ (S/PDIF or AES Data)

DGND

AES- (S/DPIF or AES Data)

DGND

EXTRA1

DGND

EXTRA2

DGND

EXTRA3

DGND

Requirement: 8x2 0.1" Connector

API 500 series

I recently did some work in Eagle (Cad software for PCB's) to create a library for the API500 (http://www.apiaudio.com/5006b.html) standard.

http://www.prodigy-pro.com/forum/viewtopic.php?t=18715

This standard looks to be an awsome standard for DIY'ers to standardise around, although I do have some concern for it's ability to deal with digital audio.

For instance, the only supplies in the standard are ±16VDC supplies. This is obviously aimed at the analog signal chain supplies. Not knowing enough about noise in digital and analog systems makes me concerned that a digital product could really spoil the supply, not only in the card that contains the analog and digital, but also the rest of the box (the other 5 units in the lunchbox).

Such "analysis" of the card and it's format really made be re-evaluate the motherboard plan that I was doing, but also look for an alternative sub-rack system. A post on group-diy pointed to something called a Frac Rak - made by Paia Electronics. http://www.paia.com/fracrak.htm

Someone mentioned in the thread that the Paia board wasn't strong enough in comparison to the API lunchbox. However, a little more research into the Fracrak shows that it is incredibly popular in the DIY Synth market. Those folks are pretty much doing what we're doing here, except that their boxes are more fixed in place (at the geeks home) :-)

I kept on chewing onthis thought, wondering on how I could strengthen the box, how I could make it so that card edge connectors could remain in place, even when the unit is under stress.

The conclusion I came to was that if you were really serious about making the unit mobile, you'd flight case it on its own (in an SKB like case). AS for card edge connectors... forget it. I'm still tempted to use ribbon connectors with 0.1" spacings. That way, if these is some bending, the card mounted vertically (e.g. the mic amp) isn't going to put pressure on horizontal board (the motherboard).

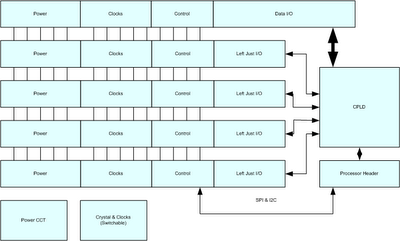

In the case of the system that will mainly be individual cards that can have audio chained from one to the other, then there isn't so much of a need for a control processor or CPLD. The main use for a motherboard system of such a kind is in the distribution of shared resources - power, clocks, control (SPI and I2C) etc.

My design experience in these fields is limited, however, I have seen many implementations in Pro Systems, and asked many a question. Any comments you have are appreciated.

Cheers,

R

http://www.prodigy-pro.com/forum/viewtopic.php?t=18715

This standard looks to be an awsome standard for DIY'ers to standardise around, although I do have some concern for it's ability to deal with digital audio.

For instance, the only supplies in the standard are ±16VDC supplies. This is obviously aimed at the analog signal chain supplies. Not knowing enough about noise in digital and analog systems makes me concerned that a digital product could really spoil the supply, not only in the card that contains the analog and digital, but also the rest of the box (the other 5 units in the lunchbox).

Such "analysis" of the card and it's format really made be re-evaluate the motherboard plan that I was doing, but also look for an alternative sub-rack system. A post on group-diy pointed to something called a Frac Rak - made by Paia Electronics. http://www.paia.com/fracrak.htm

Someone mentioned in the thread that the Paia board wasn't strong enough in comparison to the API lunchbox. However, a little more research into the Fracrak shows that it is incredibly popular in the DIY Synth market. Those folks are pretty much doing what we're doing here, except that their boxes are more fixed in place (at the geeks home) :-)

I kept on chewing onthis thought, wondering on how I could strengthen the box, how I could make it so that card edge connectors could remain in place, even when the unit is under stress.

The conclusion I came to was that if you were really serious about making the unit mobile, you'd flight case it on its own (in an SKB like case). AS for card edge connectors... forget it. I'm still tempted to use ribbon connectors with 0.1" spacings. That way, if these is some bending, the card mounted vertically (e.g. the mic amp) isn't going to put pressure on horizontal board (the motherboard).

In the case of the system that will mainly be individual cards that can have audio chained from one to the other, then there isn't so much of a need for a control processor or CPLD. The main use for a motherboard system of such a kind is in the distribution of shared resources - power, clocks, control (SPI and I2C) etc.

My design experience in these fields is limited, however, I have seen many implementations in Pro Systems, and asked many a question. Any comments you have are appreciated.

Cheers,

R

Friday, August 25, 2006

Motherboard Topology

Friday, August 18, 2006

Ahhh... after quite a delay, the boy is back in town :)

For those that have followed this project, the delay has been blamed on my recent move to Texas with work. Let's just say that the difference between the UK and Texas is bigger than I expected :)

The new job is very relevant to the parts that are being dicussed in the projects on this page and on GroupDiy... in fact, I do wonder how many of my customers actually read groupdiy :)

Anyway - I digress...

I've had to relearn my own Schematic. (I always hate that...). I figured it's worth making a point of the pinouts for the connectors in the circuit.

ADC Connectors:

Pin Function Direction

1 Data In

2 DGND

3 256fS Out

4 DGND

5 64fS Out

6 DGND

7 Word ClockOUT

8 DGND

9 DGND

10 DGND

DAC Connectors:

Pin Function Direction

1 Data OUT

2 DGND

3 256fS Out

4 DGND

5 64fS Out

6 DGND

7 Word ClockOUT

8 DGND

9 DGND

10 DGND

As the initial intention - This is a modular design based around a modular system. More on the Modular system in posts to come.

Cheers

R

For those that have followed this project, the delay has been blamed on my recent move to Texas with work. Let's just say that the difference between the UK and Texas is bigger than I expected :)

The new job is very relevant to the parts that are being dicussed in the projects on this page and on GroupDiy... in fact, I do wonder how many of my customers actually read groupdiy :)

Anyway - I digress...

I've had to relearn my own Schematic. (I always hate that...). I figured it's worth making a point of the pinouts for the connectors in the circuit.

ADC Connectors:

Pin Function Direction

1 Data In

2 DGND

3 256fS Out

4 DGND

5 64fS Out

6 DGND

7 Word ClockOUT

8 DGND

9 DGND

10 DGND

DAC Connectors:

Pin Function Direction

1 Data OUT

2 DGND

3 256fS Out

4 DGND

5 64fS Out

6 DGND

7 Word ClockOUT

8 DGND

9 DGND

10 DGND

As the initial intention - This is a modular design based around a modular system. More on the Modular system in posts to come.

Cheers

R

Subscribe to:

Posts (Atom)